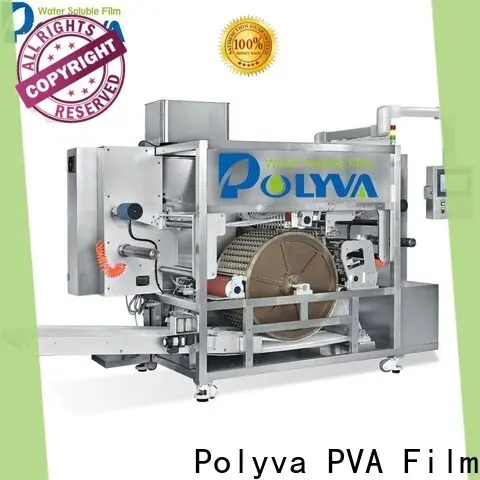

POLYVA excellent water soluble film packaging design for powder pods

1. The development of POLYVA water soluble packaging machine is professionally conducted. The mature photovoltaic power technology is adopted in its power generation system by the R&D team who spends years investigating solar products. Our laundry pods packing machine has been qualified with CE certificate

2. To be a leading water soluble film packaging manufacturer, POLYVA has been holding on providing the best service. Our R&D team is led and guided by a professor team from South China University of Technology

3. The product features maximum cooling efficiency. It effectively transfers heat by mechanically compressing refrigerant into a low-pressure, cold liquid and expanding it into high-pressure and hot gases. The adopted materials are all harmless which do no harm to human body

4. The product is abrasion-resistant. The surface of the yarn is covered with irregularly wound fibers and it is not easy to disintegrate. Also, the friction of the yarn is large enough. 0.02ml filling high precision is one of the great performance of our machine

5. The product features the desired hardness. It has resistance to localized deformation such as indentation, scratching, cutting or bending. Located in Nanhai High-tech Zone, our factory covers 3300 square meters with over 60 employees

NZD series automatic liquid pods packing machine is a rotary drum-type unit dose non aqueous liquid pods forming, filling, sealing and cutting equipment. It is an automatic high capacity water-sealing packing machine specially designed for high concentrated laundry detergent pods. It has good adaptability of water soluble PVA film and detergent liquid.

The machine is particularly suitable for packing high concentrated liquid detergent,missible oil pesticide,oil chemicals agent and some other non aqueous system contents small dose single packs.It is a preferred packing way of product upgrade.

Drum-type filling,forming,servo driving

High consistence,CNC processing mold cavity.

Mold surface treatment,double durability.

Patented water sealing design,protect film water solubility.

Plunger type measuring filling,0.02ml filling precision.

Integrated continuous cutting design,stable and effective.

PLC control,touch screen operate,high automatic,high intelligent.

Rim scrap less than 2cm,high film usage rate.

Mold system can be directly washed and cleaned by water, easier to clean and maintain.

| Min capacity | 240pcs/min |

| Max capacity | 600pcs/min |

| Forming drum | 10lanes*48row |

| Pack size | 10-30g(Customized) |

| Weight tolerance | ±0.05g |

| Power | 10KW |

| Dimension | L3500*W1150*H2350mm(apporx) |

Company Features

1. There are many authoritative awards for Foshan Polyva Materials Co.,Ltd.'s technology.

2. POLYVA aims to satisfy each customers. Please contact.

Quick link