POLYVA water soluble packaging design for liquid pods

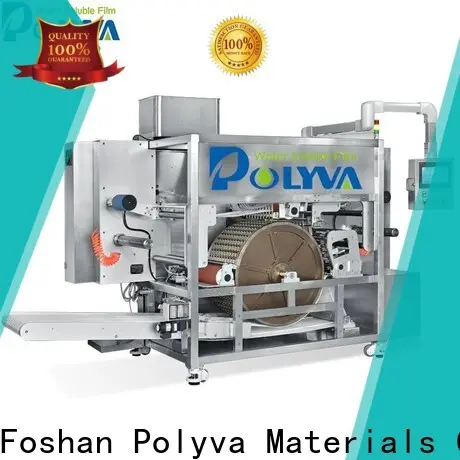

NZD series automatic liquid pods packing machine is a rotary drum-type unit dose non aqueous liquid pods forming, filling, sealing and cutting equipment. It is an automatic high capacity water-sealing packing machine specially designed for high concentrated laundry detergent pods. It has good adaptability of water soluble PVA film and detergent liquid.

The machine is particularly suitable for packing high concentrated liquid detergent,missible oil pesticide,oil chemicals agent and some other non aqueous system contents small dose single packs.It is a preferred packing way of product upgrade.

Drum-type filling,forming,servo driving

High consistence,CNC processing mold cavity.

Mold surface treatment,double durability.

Patented water sealing design,protect film water solubility.

Plunger type measuring filling,0.02ml filling precision.

Integrated continuous cutting design,stable and effective.

PLC control,touch screen operate,high automatic,high intelligent.

Rim scrap less than 2cm,high film usage rate.

Mold system can be directly washed and cleaned by water, easier to clean and maintain.

| Min capacity | 240pcs/min |

| Max capacity | 600pcs/min |

| Forming drum | 10lanes*48row |

| Pack size | 10-30g(Customized) |

| Weight tolerance | ±0.05g |

| Power | 10KW |

| Dimension | L3500*W1150*H2350mm(apporx) |

Quick link