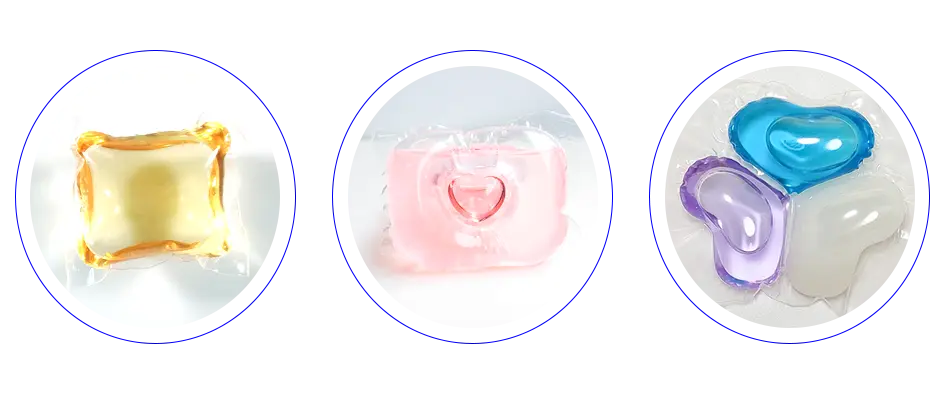

top quality water soluble packaging personalized for liquid pods2

NZE high speed automatic liquid pods packaging machine is a rotary drum-type small dose liquid capsule forming and filling equipment. The mold and vacuum system are very stable and nearly dont need any maintenance.It will only take 20 minutes to switch the mold with the same length and width,while it will take around 1 hour to switch the mold with different length and width, which effectively improves the equipment utilization.

It is especially suitable for small-dose quantitative packaging of highly concentrated laundry detergent, pesticide emulsifiable concentrate preparation, chemical oily preparation, and other non-aqueous systems. It is a preferred packaging machine for a company to update their package manner.

Can be customized shape

Drum-type capsule molding and filling, independent servo power transmission.

The mold is processed and integrated with CNC precision machine to ensure, high consistency of dimensional accuracy.

The main roller can be quickly switched, improving the equipment utilization.

The patented water seal design is adpoted,with 24 hours long-lasting working.

With a integrated split design, there is one more row of capsules per circle, to realize higher film utilization.

The mold system can be directly cleaned with clean water, and it is easier to be maintained and preserved.

Min capacity | 780pcs/min |

Max capacity | 1300pcs/min |

Forming drum | 10lanes*48row |

Pack size | 8-30g(Customized) |

Weight tolerance | ±0.05g |

Power | 15KW |

Dimension | L3700*W1500*H2350mm(apporx) |

Quick link