high quality dissolvable plastic factory for granules3

Advantages:

1. Completely dissolve, no residue left.

2. Good weather resistance,

3. Green environment-friendly material, no toxic substance contain.

4. Good mechanical property and heat sealing ability.

5. Able to be printed with good quality, ink will dissolve with the bag.

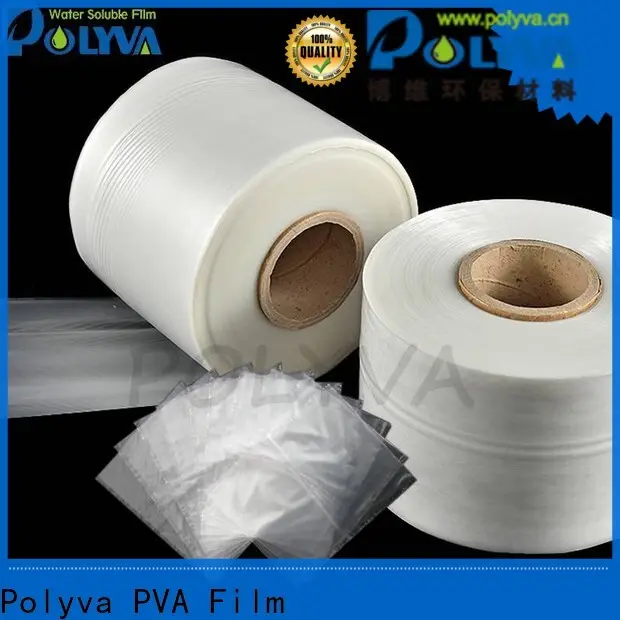

Specification:

1. Size

Bags

Produce as per customer requirements.

Roll film

Thickness(µm) | 25、35、45、75 |

Width (mm) | ≤1000 |

Length (m) | 100~1000 |

The thickness, width of the film can be produced as per customer’s requirements if the order quantity more than 10000 meters.

2. Appearance:

clear, embossing

Application:

Applicable for the single measurement package of fertilizer powder, granules, missible oil.

1. The tiny package of fertilizer powder, granules, missible oil.

2. Some products which human shouldn’t directly contact and the items used in the water.

3. The inner package of pesticide effervescent.

4. paint, dye, and some other chemical products package and seed bags

Using method

Produce the appropriate wide roll film according to the weight of the packed pesticide, then use the automatic packaging machine to pack it into single unit.

Application case

Directly put the packed pesticide unit into water, stir it slightly. The outer water soluble packaging film will be immediately dissolved to release the pesticide. So the active ingredients can be fully used and it can keep user from direct contact with the toxic substance. It will reduce the plastic pollution to the world.

product performance

1. water solubility

Test sample: 35µm thick film.

Test condition | Disintegration time (Begin) | Solution time (complete) |

Water temperature 23℃ | <<10 sec | <<40 sec |

2. Physical property

Test sample: 35µm thick film. Test condition: 23℃、50%RH

Item | Test standard | NY300 series | NY700 series |

Tensile strength MPa | GB/T 1040-2006 | ≥30 | ≥20 |

Elongation at break% | GB/T 1040-2006 | ≤300 | ≤300 |

100% stretching strength% | GB/T 1040-2006 | ≥10 | ≥5 |

Elastic modulus MPa | GB/T 1040-2006 | ≥50 | ≥25 |

Heat sealing strength 0.035mm, N/15mm | GB/T 1040-2006 | ≥5 | ≥5 |

Special Note

1, the product performance and storage and testing of environmental temperature and humidity, film thickness is directly related to the specific subject to the actual measurement.

2, the performance of different types of products there will be significant differences in the specific model to select the actual subject.

Quick link