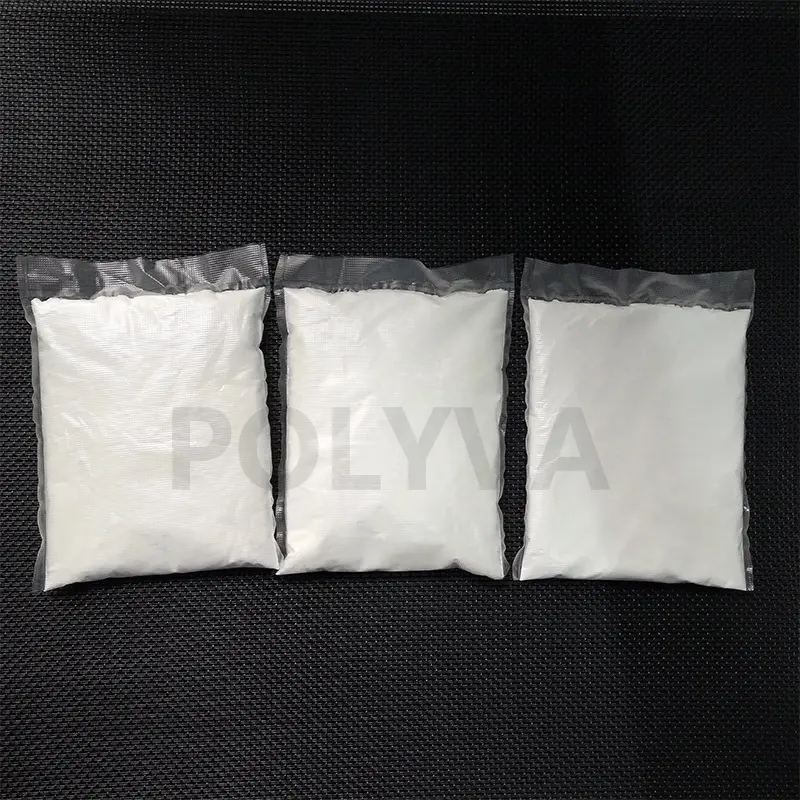

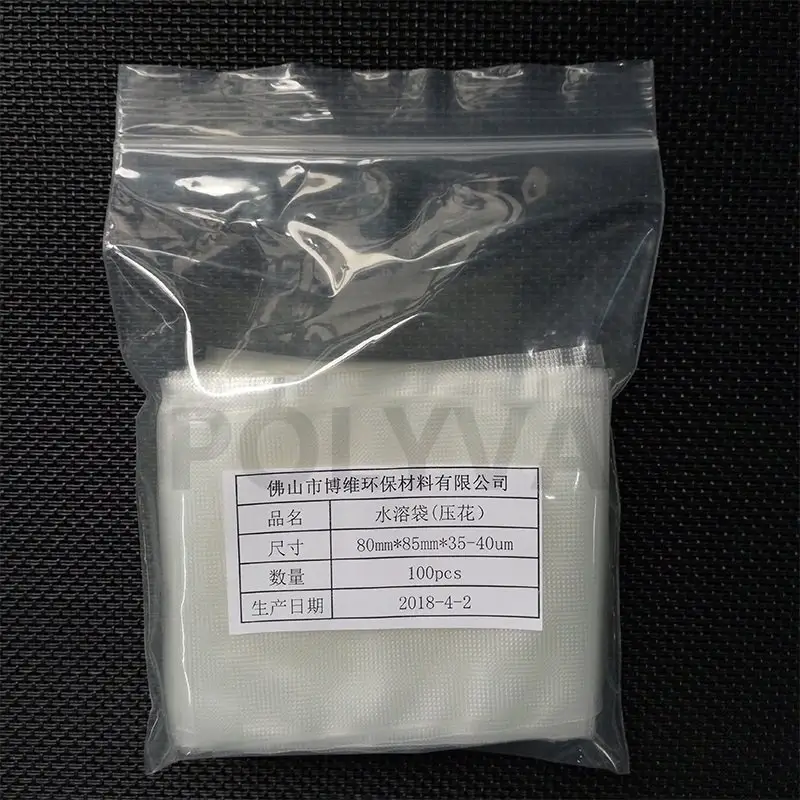

POLYVA wholesale dissolvable bags factory for granules

Agrochemicals water soluble packaging film

Product Description:

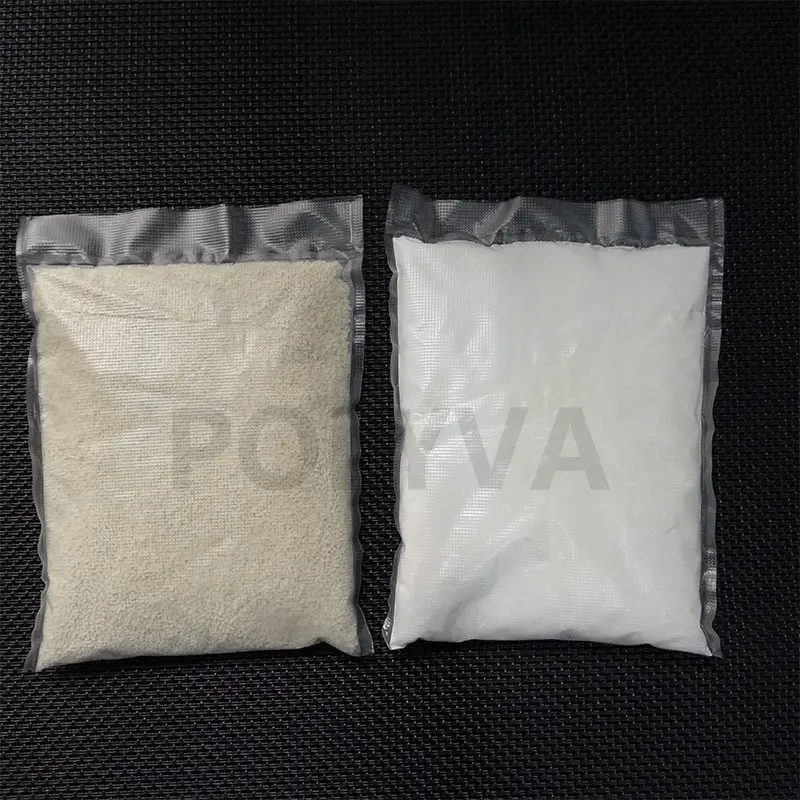

Polyva customizes applicable water soluble film according to specific purposes. L0500 series is the common water soluble film for agrochemicals packaging, it is a preferred film for normal powder packaging.

Product Features:

1、Good water solubility, completely dissolution without residue.

2、Good mechanical property and heat sealing ability, strong load bearing.

3、Good extensibility, meet the packaging need of different shape.

4、Exclusive rapid speed water solubility, good for packing contents releases.

5、Green Eco-friendly material, non- toxic substance, fully degrade in the nature.

Application

》》Specially used for unit-dose packaging of agrochemicals powder, granules, missible oil.

》》Applicable for unit-dose packaging of regular cleanser, solid chemicals, water soluble fertilizer.

Quick link