Related Products

| Brand Name | Polyva |

|---|---|

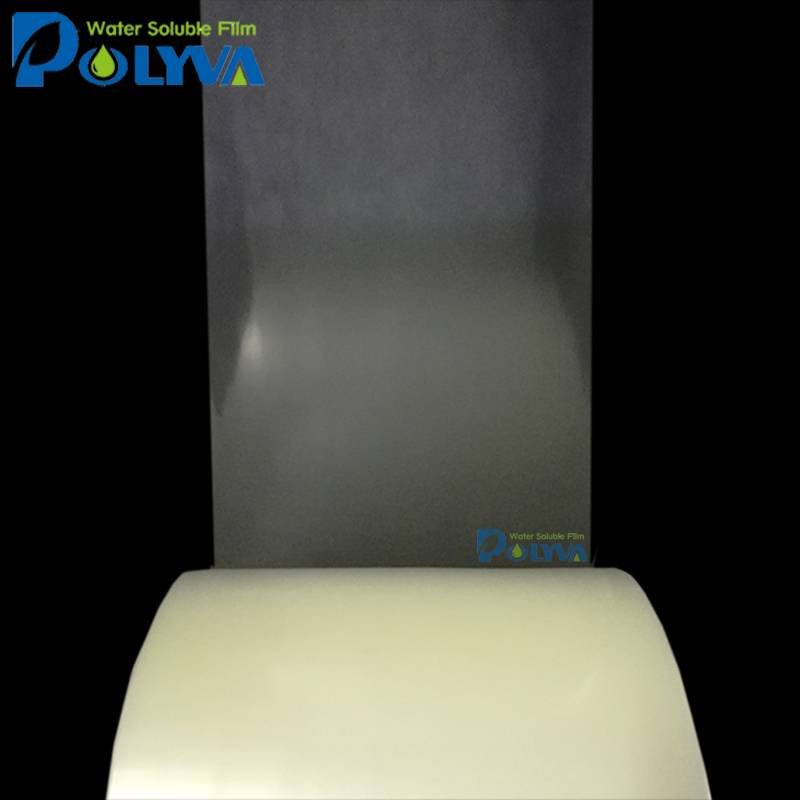

| Model: | L0900 |

| Minimum: | ≥1 tons |

| Origin: | Foshan, Guangdong, China |

| Hardness: | Soft |

| Feature: | dissoluble |

| Regular Thickness: | 75μm |

| Width: | 100mm-1800mm |

| Length: | customized |

| Product Name | water soluble film |

| Suitable for | laundry detergent pods |

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist