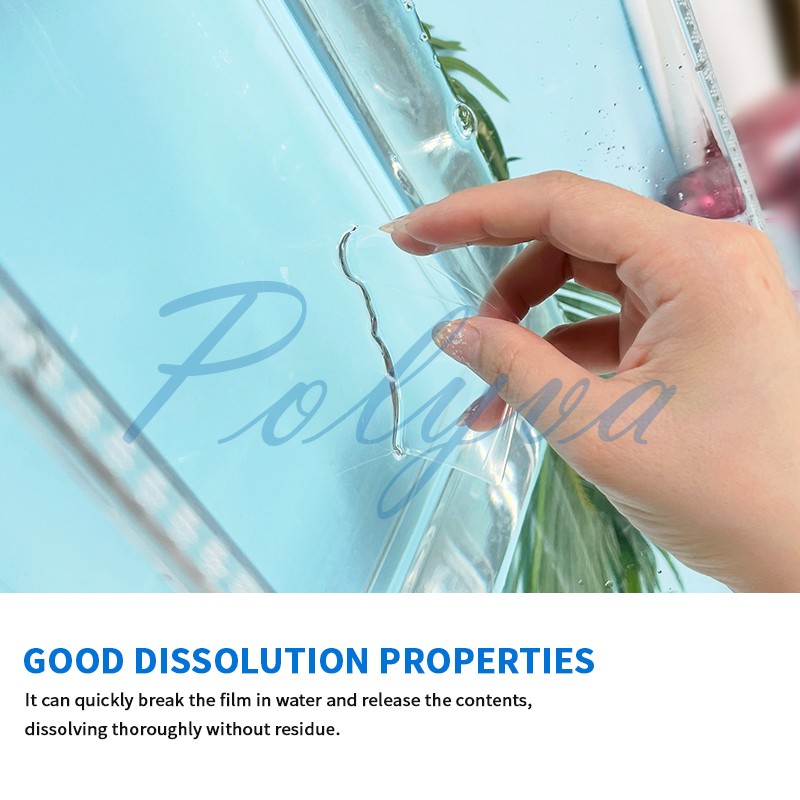

1.Able to be dissolved in normal temperature water in 10 seconds, totally dissolve in 1 minute.

2.Completely dissolve, no residue left.

3.No curling when dissolving, uniformly distribute, same solution degree.

4.Safe, environment-friendly, non-toxic, non-pollution, finally degrade into CO2 and H2O.

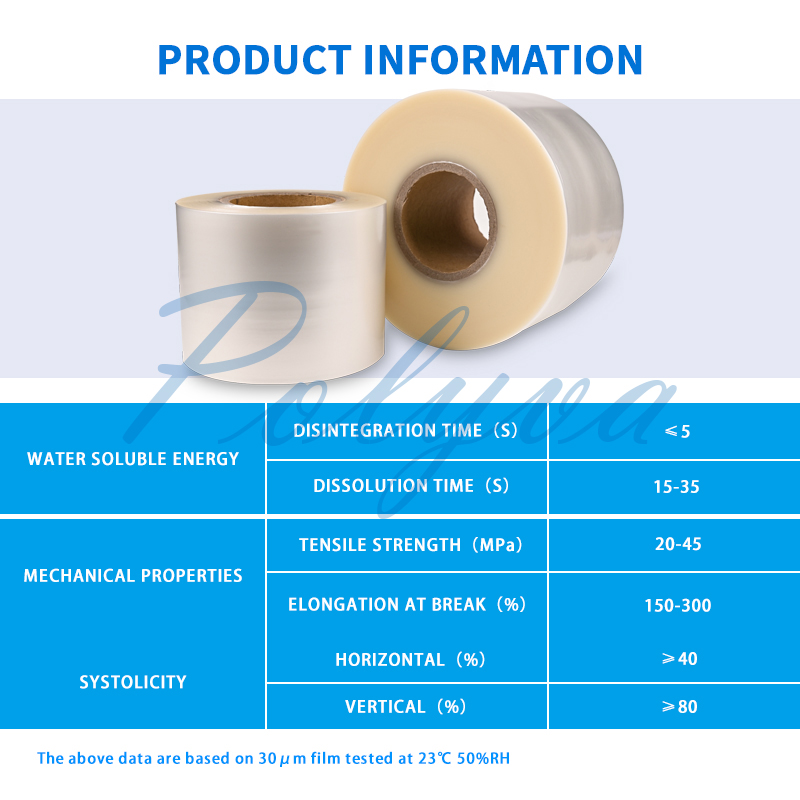

Thickness(um) | 20、25、30、35、40、45、50 |

Width (mm) | 800、1000、1600 |

Length (m) | 100~1000 |

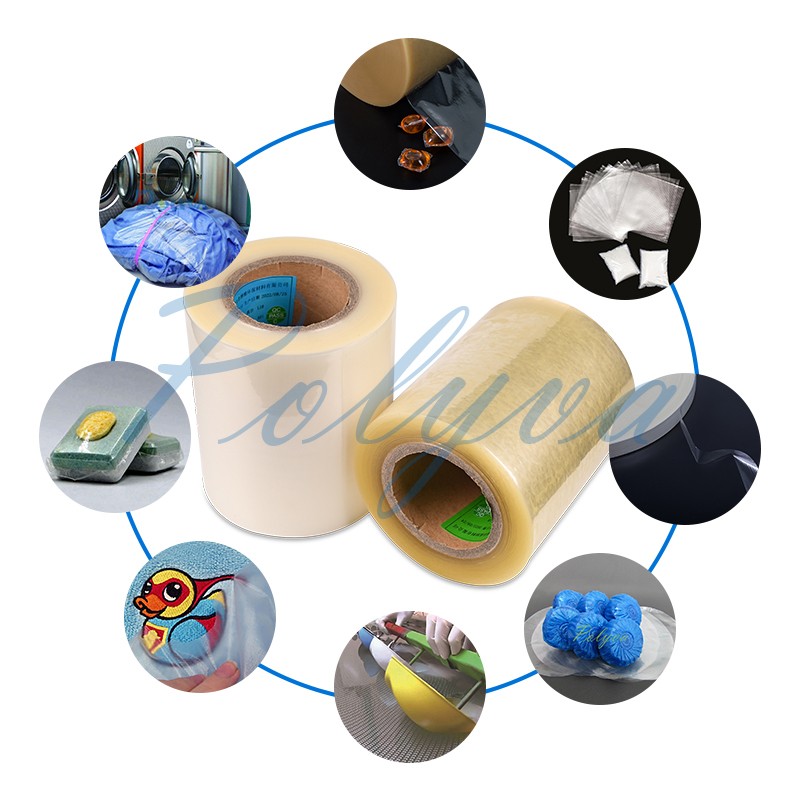

Iron, copper, ceramic, glass, nylon, fiber, wood, FRP, acrylic

Electronic products, automobile accessories, daily products, indoor building material

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist