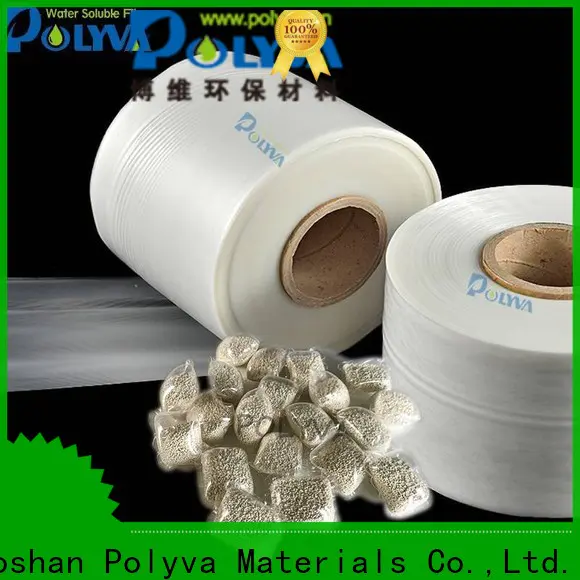

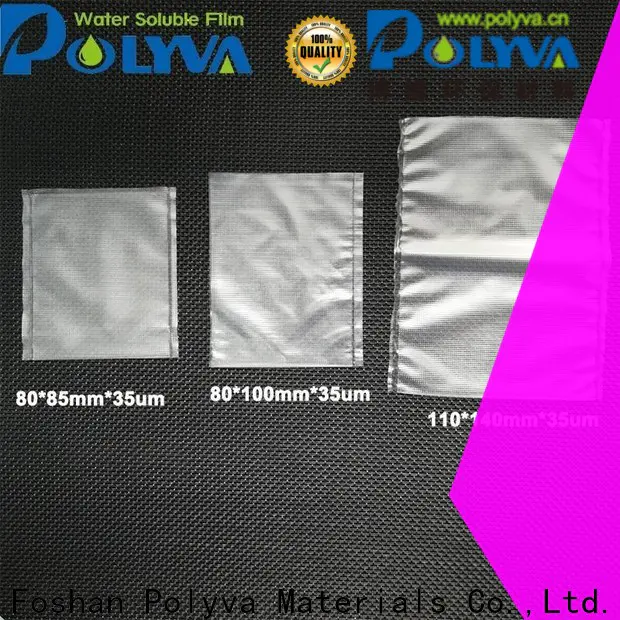

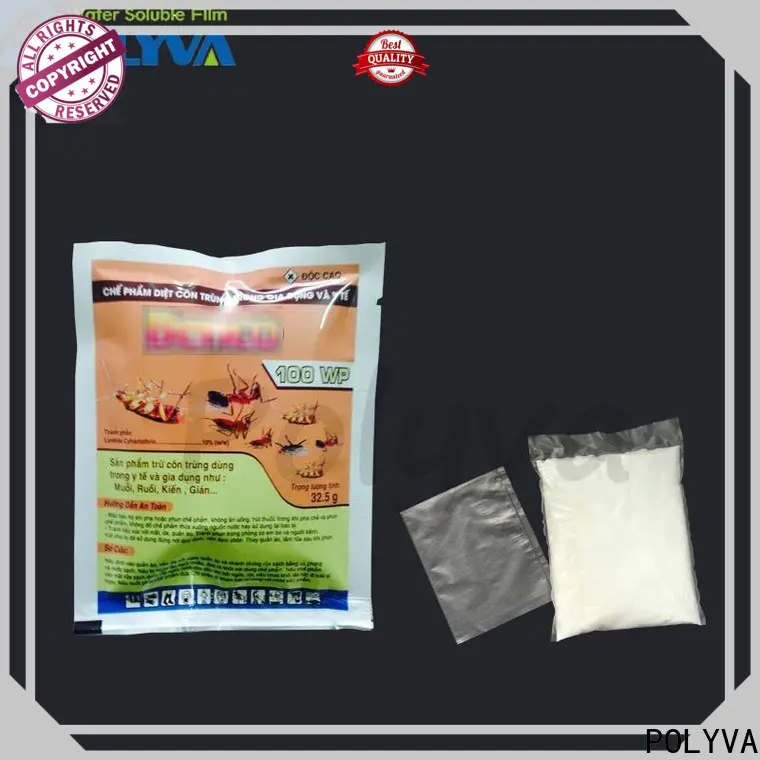

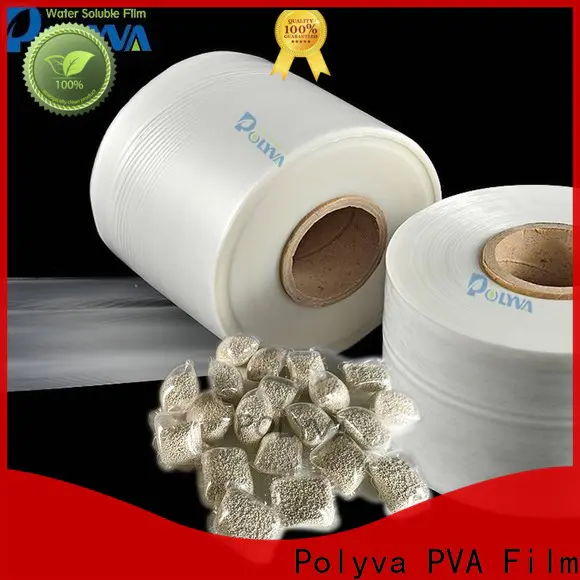

Canton Fair, the sea embraces all rivers, the 137th Canton Fair is about to open grandly. (Booth No.: 18.1 L16)As a leader in the field of water-soluble film packaging equipment, POLYVA Group is full of enthusiasm and brings a new series of products to invite you to this trade feast and witness the innovative changes in the water-soluble packaging industry together!Flexible, compact and efficient: DS-160DS-160 high-speed condensation laundry pods automatic packaging machine, the overall equipment is compact and flexible and does not occupy space, the guided interface is one-button trial production, and the fully automatic filling is integrated; independent sub-control motor, low-energy consumption lean production, efficient continuous production 6K/H, trial production directly converted to mass production, providing you with a full range of personalized service experience.Environmental protection pioneer: POLYVA Group water-soluble filmPOLYVA Group water-soluble film adheres to the concept of sustainable development, uses environmentally friendly green materials, and does not contain harmful substances. The water-soluble film has low-temperature water solubility, and can break the film and dissolve in 10℃ water within 30 seconds, and the dissolution time can be customized according to needs. In addition, the film has good mechanical properties and sealing properties, and over 400% ductility, which are sufficient to meet the packaging needs of various shapes.One-stop OEM & ODM water-soluble product exclusive customization serviceThe Jingliang laundry pods OEM business under POLYVA Group focuses on the research and development of laundry pods and peripheral products, deeply cultivates the subdivided application scenarios of daily chemical products, adheres to the three service concepts of "faster, more economical, and more stable", and provides one-stop water-soluble packaging product full-case services for brands from research and development to after-sales with three generations of laundry pods, four major formulas, and nine major functions.

Read More>>

All Products

-

Laundry Detergent Pods Factory

- Customized PVA Film

-

Laundry Detergent Pods Bulk

-

Quality PVA Packaging machine Manufacturer

-

Certificated new category

-

Hot plastic box Bulk

-

Quality Single Cavity Laundry Beads

-

Multi Cavity Laundry Beads Manufacturer

-

Sample & Inspection Machine Company

-

Quality Pods packaging machine

-

Best NZE series Exporter

-

Double Cavity Laundry Beads Factory

-

Hot Laundry pods Bulk

-

Quality Water soluble PVA film

-

Inspection Equipment Supplier

-

Hot plastic box Bulk

- Quality new category Supplier

- new category Wholesale

-

Hot PVA Packaging machine

-

Buy PVA Packaging machine

- Top PVA Film

-

Certificated PVA Packaging machine

-

PVA Packaging machine Manufacturing

- PVA Film Exporter

- Buy PVA Film

- PVA Film Warranty

- Hot PVA Film Supplier

- Certificated PVA Film Exporter

- PVA Film Factory

Hot products