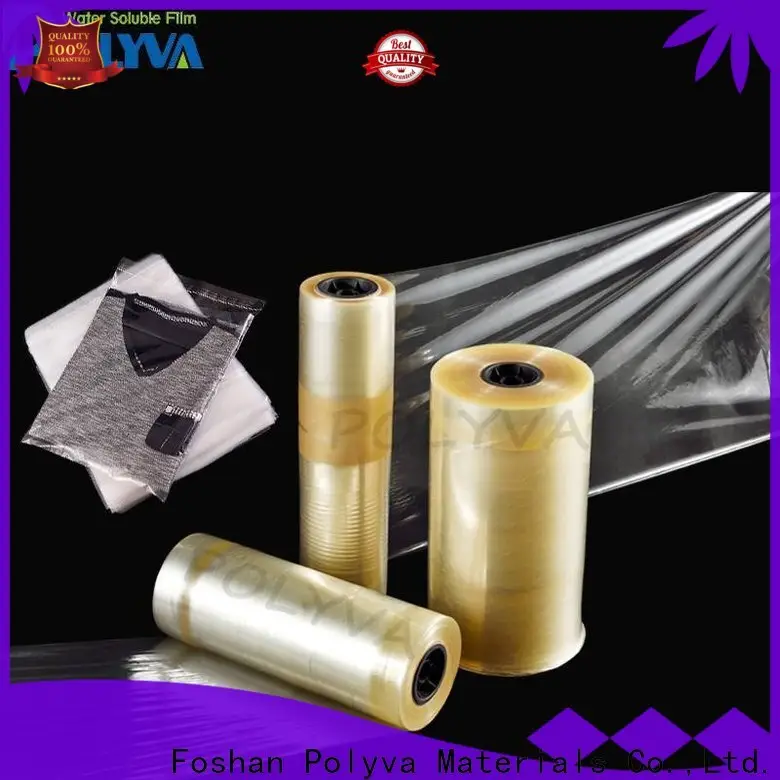

eco-friendly pvoh film series for water transfer printing

1. It is water soluble plastic film that contributes to the uniqueness of our pvoh film . Our R&D team is led and guided by a professor team from South China University of Technology

2. Foshan Polyva Materials Co.,Ltd. always defines products with standards and production guide. Our laundry pods packing machine has been qualified with CE certificate

3. The rigorous quality checking process guarantees customers a full range of quality product. 0.02ml filling high precision is one of the great performance of our machine

Features

1. Anti-static, dustproof, better show the clean and bright outlook of the clothes.

2. Good transparency, utmostly show the beauty of the goods.

3. Good barrier property, effectively avoid clothes being yellow with age.

4. Well mechanical property and heat sealing ability, strong load bearing.

5. Green eco-friendly material, no toxic substance contained.

Specification:

1. Size

Bag

Customize as request.

Roll film

Thickness(um) | 25-45(customize available) |

Width (mm) | ≤1000(customize available) |

Length (m) | 100~500(customize available) |

2. Color

Normally no color,

can be customize according to the requirements of customer.

Application:

1. Suitable for different kind of textile packaging.

2. Especially fit for sealed package of high-end garments

Company Features

1. Foshan Polyva Materials Co.,Ltd. constantly improves the product manufacturing process.

2. Our company bears social responsibility. We have been making efforts to invent new technology with low acoustic emissions, low energy consumption, and a low environmental impact.

Quick link