|

Product Name

|

Powder water soluble Pods packaging machine | |||

| Model |

NZD530-SP

|

NZD530-DP

|

NZD530-SM

|

NZD530-DM

|

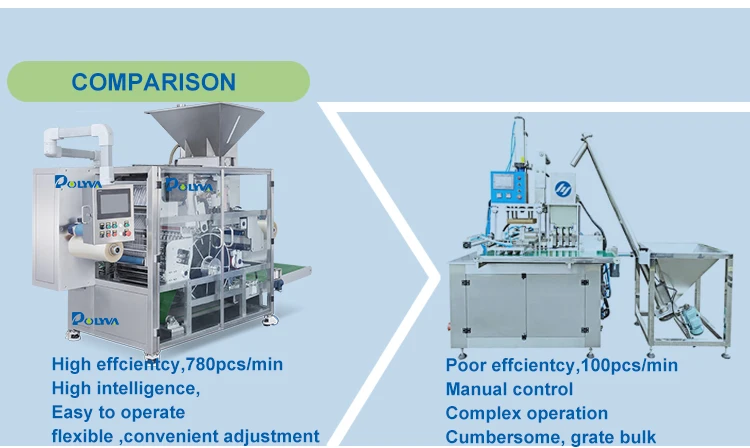

| Production Speed |

780 pcs /min

|

|||

| Packing Specification |

5-30g (customizable)

|

|||

| Weight Tolerance |

±0.3g

|

|||

|

Power

|

15Kw

|

|||

|

Dimension(L*W*H)

|

3700*1500*2450mm

|

|||

Note: Blue indicates the current machine model, gray indicates the same series of machines.

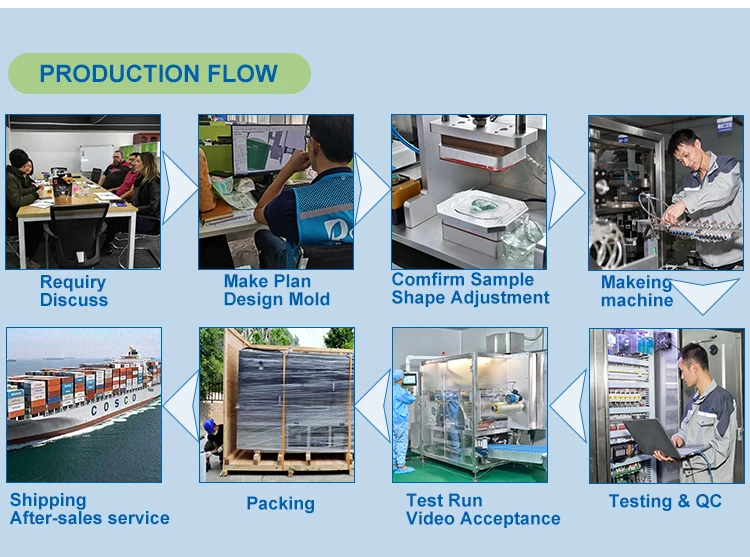

Q1. How can I get a quotation of the liquid detergent automatic filling packaging machine?

A. Contact us and we will reply you ASAP. And you may contact us directly by Trade Manager.

Q2. Can you provide customized machine or SPM (Special purpose machine)?

A. Yes, we provide modeling customized service.

Q3. Can you provide training for operation packaging machines?

A. Yes, free training in our factory is available.

Q4. How about your price?

A. Send me details about what you need, you will get the best price in China. The price is competitive over the world.

Q5. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective for a period of 12 months, starting on the machine’s bill of lading date. Please contact your POLYVA sales representative for details.

Q6. What’s the package?

A. All our automatic filling machines are packed with sea worthy package.

Copyright © 2024 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist