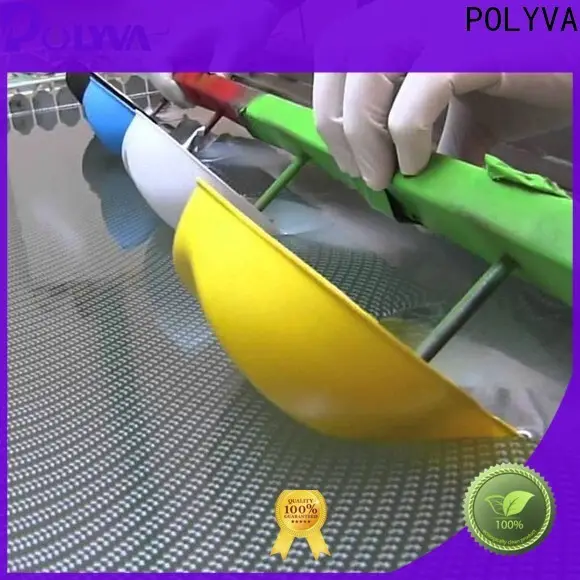

POLYVA advanced polyvinyl alcohol bags with good price for water transfer printing

Type:

Stretch film

Model:

Water transfer printing water soluble PVA film

Minimum:

≥1 Tons

Payment:

T/T,other

Origin:

China

Brand:

Polyva

Processing Type:

casting

Hardness:

soft

Feature:

Water soluble

Usage:

Water transfer printing film

Material:

Vinyl

Regular Thickness:

30um

Width:

100mm-1800mm

Length:

100M-1500M Inquire Online

Features:

1.Able to be dissolved in normal temperature water in 10 seconds, totally dissolve in 1 minute.

2.Completely dissolve, no residue left.

3.No curling when dissolving, uniformly distribute, same solution degree.

4.Safe, environment-friendly, non-toxic, non-pollution, finally degrade into CO2 and H2O.

Specification

Thickness(um) | 20、25、30、35、40、45、50 |

Width (mm) | 800、1000、1600 |

Length (m) | 100~1000 |

Application:

Applicable material:

Iron, copper, ceramic, glass, nylon, fiber, wood, FRP, acrylic

Applicable field:

Electronic products, automobile accessories, daily products, indoor building material

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

no data

Get in touch with us

Quick link

PVA Film

Why choose us

about us

Contact us

FOSHAN Head Office

Tel: +86 17796067993

Email: web@polyva.cn

Contact Person: Tony

Address: 77-3 Datang A Zone, Central Technology Industrial Zone of Sanshui District, Foshan

Türkiye Office

Address: Köseler, Kocaeli KOB Organize San. District, 25. St. No:6 Floor: 1 41455 Dilovası/Kocaeli

Authority: Muhammet Ali ACAR

Email: macr@polyva.cn

Contact: +905557526858

Copyright © 2025 POLYVA | | Sitemap | Privacy Policy