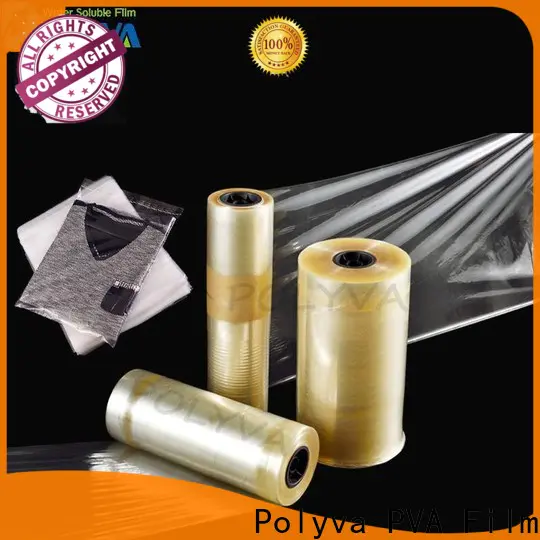

1. Anti-static, dustproof, better show the clean and bright outlook of the clothes.

2. Good transparency, utmostly show the beauty of the goods.

3. Good barrier property, effectively avoid clothes being yellow with age.

4. Well mechanical property and heat sealing ability, strong load bearing.

5. Green eco-friendly material, no toxic substance contained.

1. Size

Bag

Customize as request.

Roll film

Thickness(um) | 25-45(customize available) |

Width (mm) | ≤1000(customize available) |

Length (m) | 100~500(customize available) |

2. Color

Normally no color,

can be customize according to the requirements of customer.

1. Suitable for different kind of textile packaging.

2. Especially fit for sealed package of high-end garments

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist