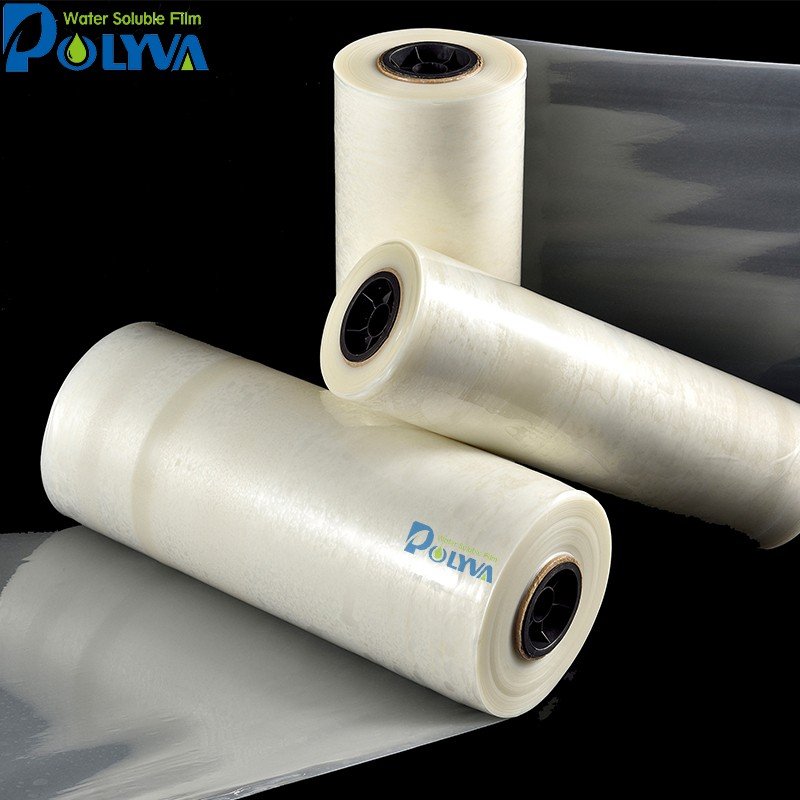

Can be normally used with packaging machine under high humidity.

With its evcellent water solubility and weather resistance.

Especially suitable for high humidity climate.

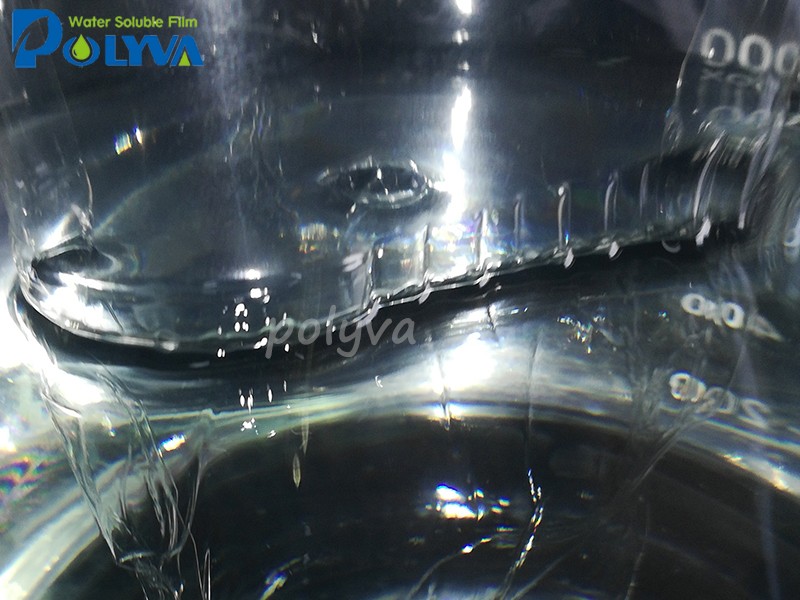

Green Eco-friendly materials,non-toxic substance full degrade in the nature.

Especially suitable for unit-dose packaging of nonionic surfactant products.

Applicable for low water soluble packaging which requires high extensibility.

Appliacble for unit-dose packaging of regular cleanser,emulsion pesticide,water soluble fertilizer.

Test sample:75um film.Test condition:23℃,50%RH.

Item | Key index | L0200 |

Machanical property ( GB/T1040-2006) | Tensile strength | 25-35 |

| Elongation | 350-450% | |

| Modulus | 100-200% | |

| Water solubility (QD08-09-02) | Disintegration tiom | 23-32 |

| Dissolution time | 55-70 |

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist