BETTER TOUCH BETTER BUSINESS

Contact Sales at POLYVA.

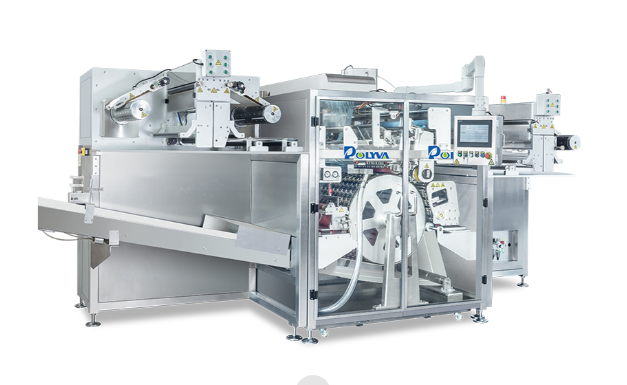

The Laundry Pods Packaging Machine is essential for producing high-quality, convenient detergent pods that meet the growing demand for household cleaning solutions. These machines guarantee accuracy and efficiency by streamlining manufacturing.

Winter, though, presents unique difficulties for their usefulness. Cold temperatures might affect essential components, including water systems, moving parts, and seals, causing malfunctions or lower manufacturing quality.

Ignoring seasonal maintenance could lead to frozen water lines, more part wear, and uneven operation conditions, compromising pod quality. This tutorial will guide you through five must-know ideas for keeping your laundry pod manufacturing machine in optimum condition all winter.

Regular inspection and cleaning of your POLYVA laundry pod-making machine are vital to ensure optimal performance, especially during winter. Internal and external components need care since neglect could cause mechanical problems, residue development, and lower efficiency. Maintaining constant pod quality and extending the lifetime of your equipment depends on keeping your machine in peak condition.

Start by concentrating on the seals, molds, and hopper since these components are essential for seamless functioning. Please turn off the machine first so that it cools down. Empty the hopper, then use a soft brush or cloth to remove any last bits of detergent or trash. Run warm water and a little cleaning chemical to remove residue from molds without harming the surfaces. Seals should be wiped carefully to prevent cracks or hardening caused by cold temperatures.

In winter, residue buildup is more likely due to the viscosity changes in detergent materials. To combat this, clean the machine after each production cycle and ensure no moisture remains, as freezing temperatures can solidify residues.

Regularly inspecting and cleaning your laundry pods packaging machine reduces the risk of unexpected downtime, ensures product quality, and protects your investment during the colder months. Consistent care now can save significant costs and hassle later.

Freezing conditions could seriously threaten the water systems of your washing pods manufacturing machine. Frozen water lines or pumps could crack or become blocked, causing expensive repairs and production delays. To avoid this, it is crucial to use antifreeze solutions, especially those meant for your laundry pod packaging machine in winter.

Select an antifreeze solution that is safe for water systems and suitable for your machine. Check the manufacturer's recommendations to ensure the fix won't damage internal parts. Avoid generic antifreeze products containing harsh chemicals or additives inappropriate for your equipment.

Start by emptying the water pipes to ensure no leftover water remains to ready your laundry pod making machine. Mix the antifreeze solution as the manufacturer directs, then run it through the system flushing. This procedure guarantees that all internal channels remain clear and functional and helps against freezing. Flushing the antifreeze entirely with clean water will help to prevent contamination of manufacturing products once temperatures steady or winter finishes.

Cold weather can significantly impact the efficiency of your laundry pods-making machine and the quality of the pods it produces. Low temperatures could cause materials to thicken, machinery to run slower, and seals or other components to stiffen, therefore producing variations in output. Ensuring flawless operation and high-quality production during winter depends on keeping ideal operating temperatures.

To avoid these issues, ensure that the workspace temperature remains consistent. Keep the room within the recommended operating range specified in your machine's manual. You can achieve this by using space heaters or insulation to prevent cold drafts. Monitor the ambient temperature regularly with a thermostat to ensure stable conditions throughout production.

Consider using heating pads or insulated covers for sensitive machine parts. Heating pads can prevent key components from becoming too cold to function efficiently, while insulated covers help retain heat during idle periods. These measures ensure that the machine stays at a stable temperature, reducing the risk of errors or wear.

Lubricating the moving parts of your machine is essential during colder months to ensure smooth operation and prevent unnecessary wear. Low temperatures can cause lubricants and greases to thicken, increasing friction and rendering parts prone to stiffness, which can, over time, cause malfunction or irreversible damage. In demanding winter, appropriate lubrication protects the lifetime and performance of your machine.

Use lubricants, especially for low temperatures. Ideal synthetic or cold-weather-grade lubricants preserve viscosity and efficacy even in freezing temperatures. Steer clear of conventional lubricants that can freeze or lose efficacy in the cold. Manufacturer-recommended goods in your machine's manual will help guarantee they fit your equipment.

Scheduling professional servicing for your laundry making machine is crucial to ensure optimal performance and longevity during the winter months. A winter tune-up by a licensed technician addresses seasonal issues that might not be readily apparent during regular maintenance. Expert maintenance guarantees your machine runs as it should and is free from expensive downtime during peak output.

During servicing, technicians can conduct a comprehensive winter-readiness check. This typically includes inspecting water lines, seals, and moving parts for wear or damage caused by colder temperatures. They also assess the machine’s electrical components, recalibrate systems if needed, and ensure all lubricants and antifreeze solutions are correctly applied. These steps are essential to prevent malfunctions that could hinder production.

Clean your machine after every manufacturing cycle to avoid residue accumulation, which can be more troublesome in colder climates. Frequent cleaning guarantees stable pod quality and smooth running.

No, regular antifreeze may contain harsh chemicals that could damage your machine. Always use antifreeze solutions recommended by your machine’s manufacturer, specifically designed for water systems and safe for the materials used in your machine.

Unusual noises, trouble keeping temperature, variable pod quality, leaking water, or inability to start indicate that your machine might need quick servicing. If you exhibit any of these signs, it is imperative to get a professional inspection to prevent further damage.

Keeping your laundry pod packaging machine running during winter is crucial for maintaining constant production quality and avoiding expensive breakdowns. Every action helps to maintain the lifetime and performance of your equipment. Antifreeze solutions and temperature control guard critical components from freezing, while regular cleaning and lubrication minimize accumulation and friction. Expert service guarantees that any possible problems are rectified before they become more serious.

By being proactive about winter maintenance, you limit downtime, lower repair costs, and guarantee consistent performance of your Laundry pod-making machine throughout the season. Your POLYVA machine will generate premium pods with the correct care, satisfying your company's needs year-round.

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist