BETTER TOUCH BETTER BUSINESS

Contact Sales at POLYVA.

Laundry pods have made household cleaning easier and more efficient. But for manufacturers, creating these pods is a detailed process that relies on advanced machines and careful planning.Laundry pods making machines and their packaging counterparts are the backbone of this production. Despite their advanced design, these machines may face challenges that can affect productivity.This article will discuss common problems faced in laundry pod production, solutions to optimize workflows, and how POLYVA's innovative laundry pods packaging machine can address these challenges.

Laundry pods have become one of the best inventions, making laundry comfy and less messy for so many people.

Such products are manufactured by laundry pods-making machines to create the structure of forming, filling, and sealing laundry detergent in water-soluble film pockets.

The current machines are helpful in guaranteeing quality production that will meet customers’ needs, besides being economical and easily scalable.

Producing high-quality laundry pods demands you address operational challenges; otherwise, it can disturb efficiency and product consistency. Below are some common problems faced during production and practical solutions to overcome them.

Proble | Cause | Impact | Solution |

Film misalignment | Improper loading of PVA film | Irregular pods or waste | Ensure proper film loading and tension |

| Inconsistent filling volumes | Calibration errors in the dosing system | Overfilling or underfillin | Regular calibration and testing |

| Sealing defects | Inadequate temperature or pressure control | Leaky or non-durable pods | Monitor and adjust sealing settings |

| Machine downtime | Lack of routine maintenance | Reduced production efficiency | Schedule preventive maintenance |

| Packaging errors | Misconfigured packaging machine settings | Misconfigured packaging machine settings | Regularly inspect packaging settings |

Film misalignment occurs when the PVA film is improperly loaded or tensioned in the machine. This can result in irregularly shaped pods or wasted materials, which increases production costs and reduces efficiency.

Suggested Solution: Ensure that the PVA film is loaded and tensioned correctly. Automated alignment systems can significantly minimize these errors.

Tip: POLYVA, a reliable laundry pods packaging machine manufacturer, produces machines that feature automated alignment systems that adjust the film in real time, reducing waste and ensuring uniform pod quality.

Inconsistent filling arises when the dosing system is incorrectly calibrated, leading to filling levels that do not match the intended settings. This may result in overfilled pods that leak or underfilled pods that fail to meet quality standards.

Suggested Solution: The dosing system should be adjusted regularly and tested for accuracy.

Tip: Machines like POLYVA offer features for adjusting frame sizes with minimal human intervention, ensuring high accuracy in filling.

Sealing defects often stem from improper temperature or pressure control during the sealing process. Poor seals can cause pods to leak, affecting product quality and customer satisfaction.

Suggested Solution: To achieve a consistent and durable seal, closely monitor sealing temperature and pressure parameters and adjust as needed.

Tip: POLYVA machines include smart temperature controls in their sealing process to help prevent defects.

Another potential issue due to a low level of maintenance is high machine downtime which leads to multiple problems and decreased production effectiveness.

Suggested Solution: Carry out a regular maintenance schedule program, aiming to detect probable problems with the machines in advance so that they will not cause failures.

Tip: The POLYVA machines are designed with easily accessible interior points where there is a need for the machines to be worked on, this reduces production downtimes.

Packaging errors, such as incorrect labeling or sealing, often result from improper machine configurations. These mistakes can disrupt the supply chain and harm brand reputation.

Suggested Solution: Ensure proper machine setup and conduct regular checks to prevent errors in labeling and sealing.

Tip: POLYVA machines provide advanced configuration options to ensure precise and reliable packaging processes.

Let’s find out why the laundry pods making machine creates issues:

● Temperature fluctuations during sealing.

● Uneven sealing pressure or misalignment.

● Contaminants on sealing surfaces.

● Nozzle blockages disrupt detergent flow.

● Inconsistent detergent viscosity causing inaccurate filling.

● Pump malfunctions lead to irregular dispensing.

● Film sensitivity causes tears or misalignment.

● Static electricity causes the film to stick or fold improperly.

● Poor storage conditions degrade film quality.

● Wear and tear of mechanical components.

● Overloading the machine beyond its capacity.

● Insufficient lubrication of moving parts.

● The defective or low-quality film leads to production inconsistencies.

● Improper detergent mixing causes clumping or uneven distribution.

● Environmental fluctuations affecting film and detergent properties.

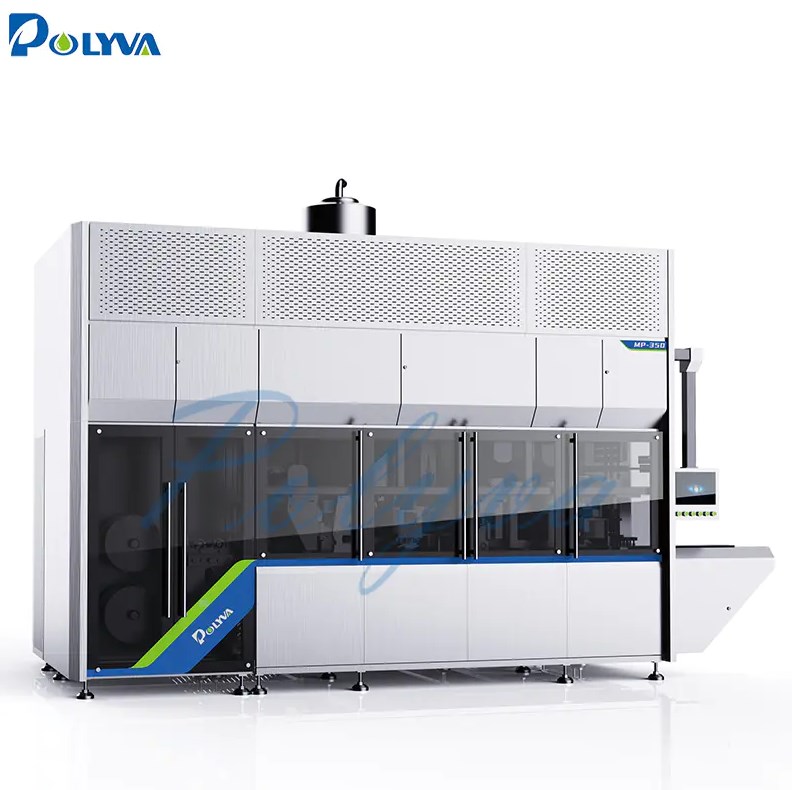

POLYVA is a trusted partner in the laundry pods packaging machine manufacturing industry, offering key advantages for businesses seeking quality and efficiency:

POLYVA uses the latest manufacturing technology to ensure efficient and precise production. Their systems streamline procedures like dosing, filling, and sealing, deliver consistent quality, and reduce waste.

POLYVA supports the environment by offering equipment compatible with biodegradable PVA (polyvinyl alcohol) films. This helps businesses meet eco-conscious consumer demand and comply with environmental regulations.

POLYVA offers tailored solutions to fit specific production needs, including customizable pod sizes, shapes, and formulations for liquid, powder, or multi-chamber laundry pods.

With POLYVA, you gain more than just equipment. They provide:

● Training: Ensuring effective operation and maintenance.

● After-Sales Support: Quick assistance to minimize downtime.

● Maintenance: Regular servicing to optimize performance.

By partnering with POLYVA, you can enjoy innovative technology, sustainable solutions, customizable options, and dedicated support to succeed in the competitive laundry pods market.

Key Features of POLYVA Machines

● Precision: Ensures accurate filling and secure sealing to maintain high product quality.

● Efficiency: Designed for high-speed production with reduced downtime to boost productivity.

● Customization: Offers flexibility to produce pods in various sizes, shapes, and detergent formulations.

● Eco-Friendly: Fully compatible with biodegradable PVA films, supporting sustainable manufacturing.

POLYVA’s laundry pods packaging machines combine advanced technology with eco-conscious designs for superior performance.

Optimizing workflow in laundry pod production is crucial for maintaining efficiency and meeting consumer demands. Manufacturers can achieve enhanced productivity and product quality by addressing common problems with practical solutions and leveraging POLYVA’s advanced machines.

Ready to revolutionize your laundry pod production? POLYVA’s innovative laundry pod-making and packaging machines are here to streamline your workflow and enhance efficiency.

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist