The Leading Laundry Detergent Pods

Total Packaging Solution provider in China

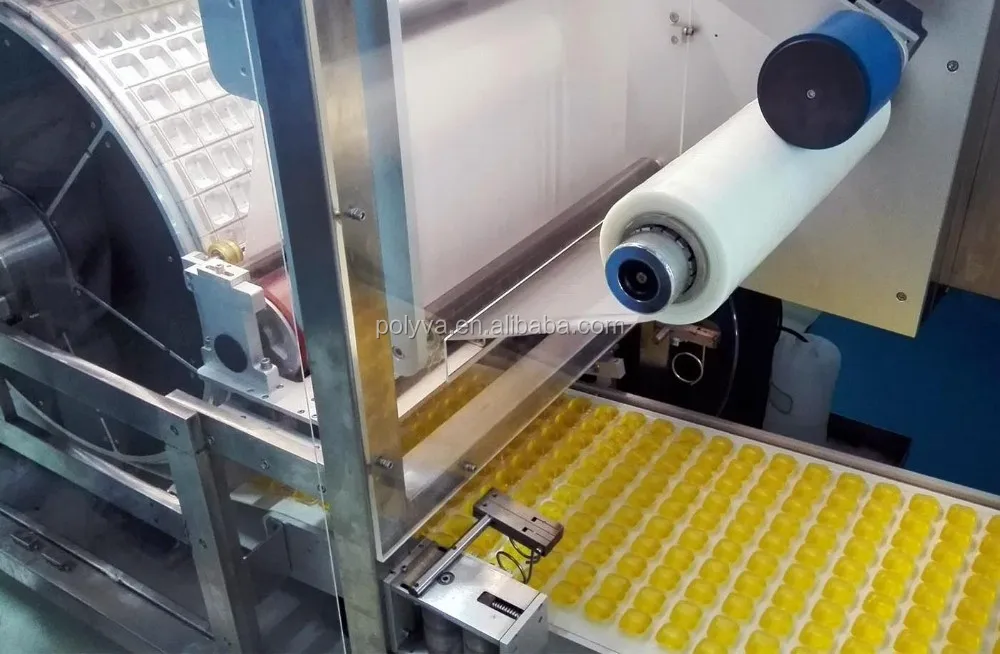

We manufacture PVA film & high capacity packing machine specially for laundry capsules

We provide OEM service!

Lab-scale detergent pods sample making machine

replaceable mould

Able to make different type of capsules

used for making capsules sample to test the compatibility between packed content and water soluble film

Parameter Sheet

Min Capacity | 300pcs/min |

Max Capacity | 600pcs/min |

Forming drum | 10 lanes * 48 row |

Packing volume | 10-30g(customized) |

Weight tolerance | ±0.05g |

Dimension | L3500×W1150×H2350mm |

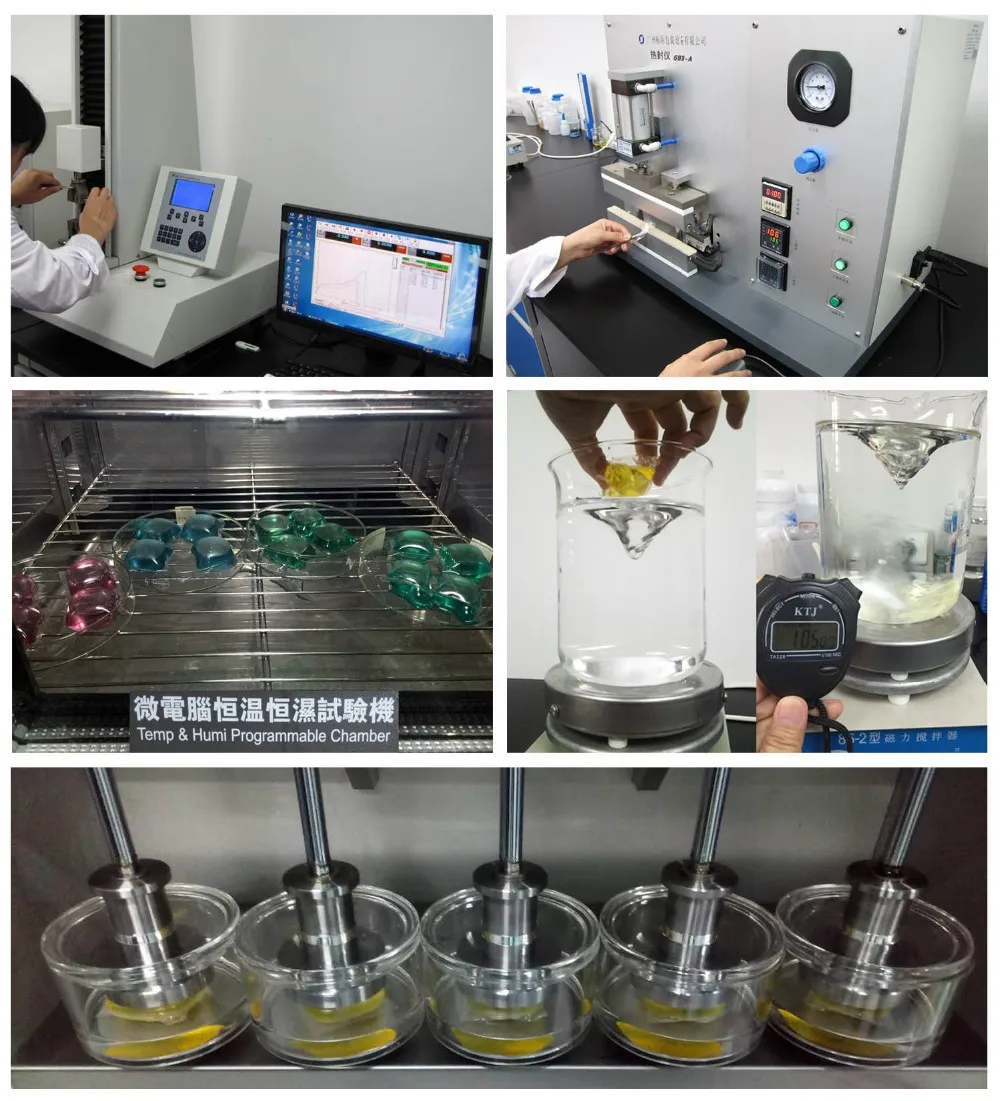

Machine trail and customer training

Film & Pods testing

Q. What are the main application of PVA film ?

A.:The main application of PVA water soluble film includes liquid or powder laundry detergent pods packing, pesticide packing , water transfer printing ,medical laundry bags and so on.

Q. What is the advantage of PVA water soluble detergent packets over the regular detergent packaging ?

A.:Using the single dose detergent packet is more convenient, more rational, more scientific and greener

Q. What machinery can run water-soluble films?

A. Horizontal flow wrapping machines, thermoforming machines and vacuum forming machines (horizontal and rotary) may run this film. Vertical Form Fill, Seal machines (trans wrap type), some types of stick pack machines, some types of 3 side and 4 side seal Vertical Form Fill and Seal machines, pleat wrapping and cut and wrap block wrapping machines are all able to run water-soluble films.

Q. How much weight can a water-soluble bag hold?

A. Laundry bags are expected to contain a maximum of 12kg (26 lbs) of linen when loaded into a supporting outer transport bag. Chemical packages are typically up to 10kg, though there is not theoretical reason for higher loadings given correct filling and handling.

Q: what are the special advantages of your products?

A: our company's product raw material USES all is harmless material, assure user's safety.

Our products are more suitable for packaging machine and improve packaging efficiency.

Our company's product weatherability reaches the same level of foreign products, as far as possible to reduce the customer's use of environment and storage environment requirements.

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist