BETTER TOUCH BETTER BUSINESS

Contact Sales at POLYVA.

An increasing number of people are using dishwasher tablets as they are easy to use, eliminate, and dispense exactly as needed. Among the branches involved in the creation of such tablets, the dishwasher tablets packing machine plays a very significant role since it can be used to pack the tablets targeted for home care and other daily chemicals as a commercial product. These machines are definitely the requirements to produce packets that are sealed properly and are of uniform size and quality. Dishwasher tablet packing machines assist in improving the speed of packaging of these detergent products and also help in the safe use and handling of the products, making them ideal for modern manufacturing practices.

The dishwasher tablet packing machine consists of parts that work in target roles such as the assembly of packed products, and consequently increase the speed and reduce errors, ensuring that optimal packaging conditions are achieved. Let’s look at the main components of this type of machine and their roles.

Tablet Feeder: This part contains the dishwasher tablets which can be molded directly or pre-formed into shape and are arranged in a position where feeding to the packing line is automatic.

Film Unwinder: The film unwinder is used to dispense packaging films whenever needed and it securely holds the tablet packaging films, which are normally water-soluble. It helps to minimize disruption of the production flow by allowing the film to move along the conveyor and item as required.

Sealing System: The sealing system, the packing element needs heat or pressure to ensure that the package is appropriately sealed over each tablet within the packing machine. Different customized packing machines can set different seal patterns that help in strong seal and leakage proof.

Cutting Mechanism: This section cuts the film between each tablet, creating individual, ready-to-sell packages. It ensures precise cuts that maintain the integrity of each sealed pack.

Control Panel: The control panel helps the operators manage the speed of the machine and temperature for sealing in relation to the requirement of the specific production. For easy adjustments and error corrections, touchscreen interfaces are available in certain models.

Using all these components in the same direction and working from the PDL-5 dishwasher tablet packing machines are capable of creating stability and packaging processes of the same height and appearance that improve the packing quality of the product on the shelves and its further consumption.

The application of dishwashing salon tablet packing machines is quite varied and widespread in various industries, primarily household and everyday chemical industries. They are also important for firms who are in production of the dishwasher tablets as these tablets necessitate the bio-degradable film that should dissolve during use. These machines are also applied to similar water-soluble being used in the package of washing-up tablets.

The machines are used by manufacturers in the home care industry to provide tapes that are individually packed and are easy to use thereby avoiding accidental spillage or misuse. The dishwasher tablet packing machine is necessary to encase every single tablet in sanitary pouches to avoid spillage and improve the shelf life of the tablets.

Water soluble sachets have found application in the daily chemical industry and bulk packing due to the ease of dispensing the right quantity and reduction in packaging waste. The dishwasher tablets packing machine is made to cater to several different formulations of the tablets and the different wrapping requirements hence its versatility in various water soluble products. With their emphasis on accurate and efficient packaging, these devices enable manufacturers to uphold high-quality standards, achieve uniformity, and provide an appealing product to eco-friendly customers.

Inside a dishwasher tablet packing machine, each type of tablet undergoes a well-organized series of movements that ensures it is correctly packaged once and for all. Here’s a breakdown of how it works:

Tablet Loading: First, the pre-formed dishwasher tablets are loaded into the machine’s tablet feeder. This component arranges the tablets into a single line, allowing them to enter the packaging system one by one.

Film Dispensing: Next, a water-soluble film, often made from polyvinyl alcohol (PVA), is unwound from the film dispenser and carried forward to meet the incoming tablets. The film is positioned carefully to cover each tablet fully.

Sealing: Once a tablet is placed onto the film, the machine’s sealing system applies heat or pressure to encapsulate the tablet, ensuring the package is tightly sealed on all sides. This seal not only prevents moisture from entering but also keeps the detergent tablet intact during transport and storage.

Cutting and Separation: The sealed packets move to the cutting section, where the film is precisely cut between each sealed tablet to form individual units. This cutting mechanism guarantees that each tablet remains in a completely sealed, single-use pack.

Quality Control and Ejection: Finally, quality checks are often conducted to detect any defective or poorly sealed packages. Once the quality assurance is complete, the finished packages are ejected and prepared for further packaging or shipping.

This process within a dishwasher tablet packing machine enables manufacturers to meet high-volume production needs with consistent quality, making these machines an invaluable asset in the packaging industry.

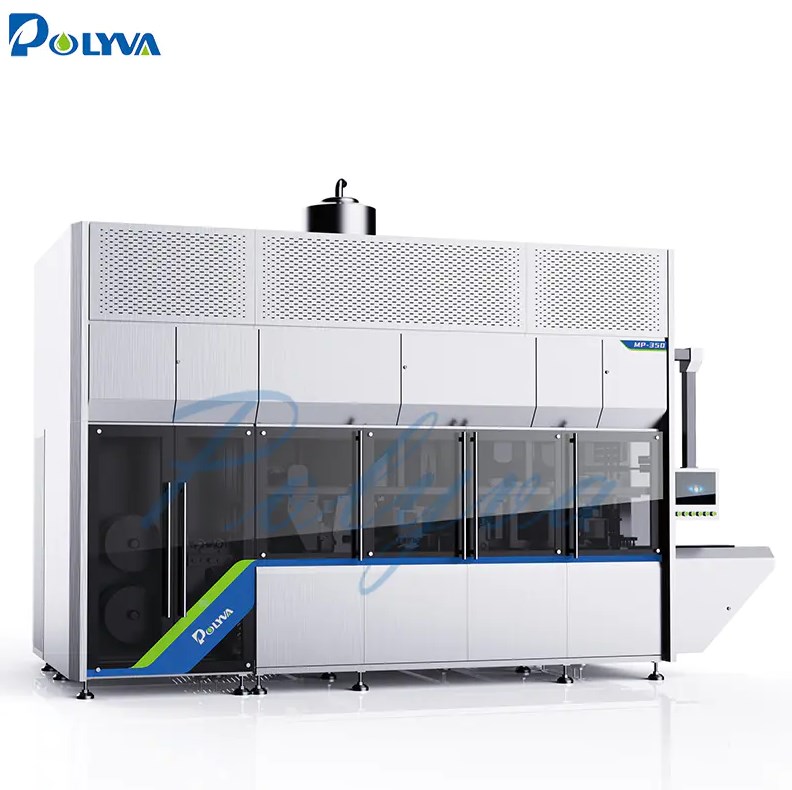

Polyva offers a cutting-edge solution in the form of its DS Series automatic high-speed dishwasher tablet packing machine. This machine incorporates the latest in rapid conversion production technology, advanced filling techniques, and four-dimensional cost-reduction technology. These innovations enable manufacturers to produce dishwasher tablets more efficiently, lowering production costs and enhancing the speed of the packaging process.

The Polyva DS Series uses a volume manufacturing approach that is suitable for the daily chemical and home care industries. This series permits quick changes of products, which is required in manufacturing processes that involve more than one type of product on the same line. Furthermore, the DS Series operates within a stable production process, facilitating prompt packaging of goods without sacrificing quality or uniformity.

The company’s focus on cost-effective and environmentally friendly practices is reflected in the packaging machine for dishwasher tablets manufactured by Polyva. Modern machinery guarantees an economy of raw material resources in a high-speed process that is in high demand in the current market conditions. As far as Polyva’s dishwasher tablet packing machine is concerned, it can be regarded as an inventive and economical machine for companies that wish to enhance their operational efficiency, cut down excess materials, and enhance productivity.

Polyva’s dishwasher tablet packing machines represent the latest advancements in high-speed, water-soluble packaging technology. With a significant presence in the market, Polyva comes in handy to help companies increase their production competitiveness and tap the expanding market for dishwasher tablets.

Copyright © 2025 Foshan Polyva Materials Co., Ltd | All Rights Reserved Design by www.polyva-pvafilm.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist